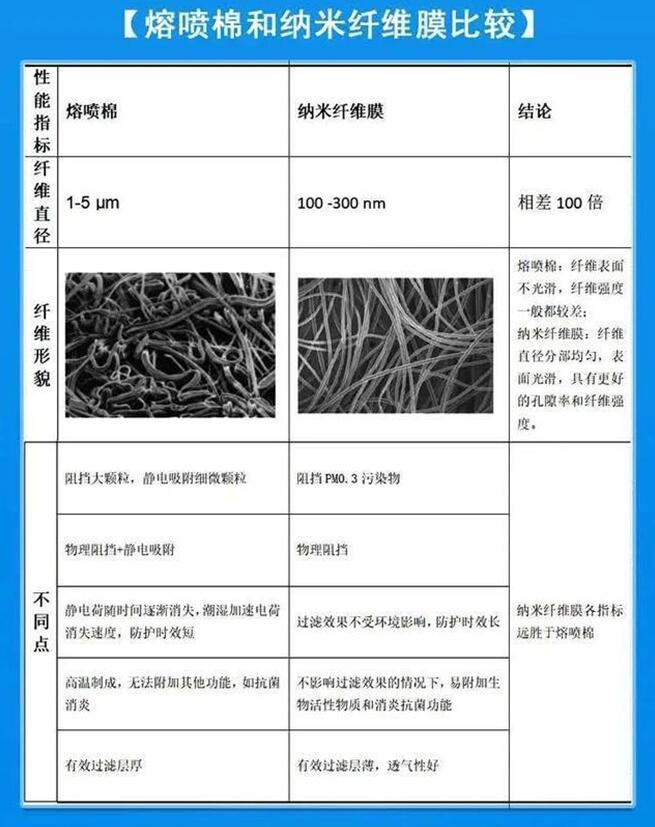

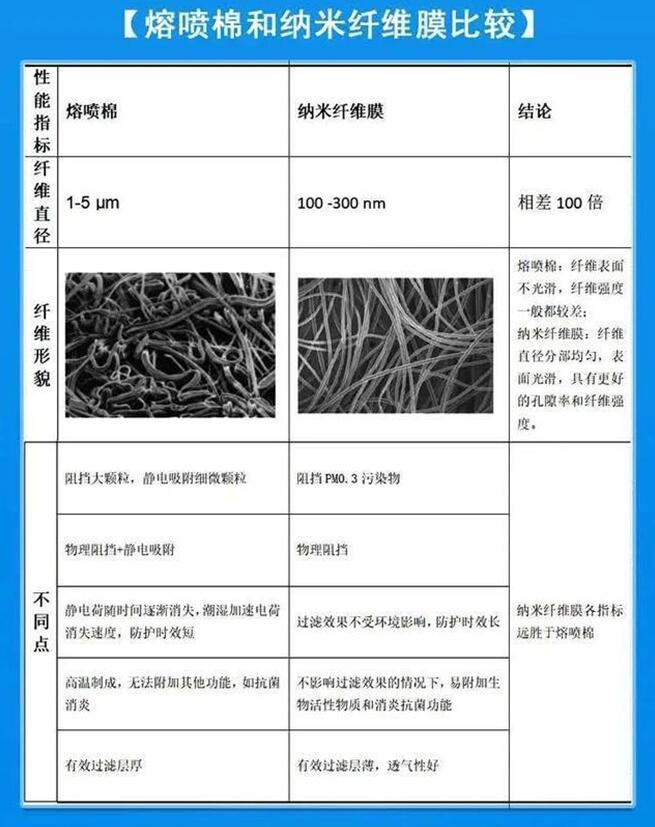

PTFE microporous membrane has high filtration efficiency, good air permeability, long-term storage efficiency will not be reduced, and it can be reused after washing or disinfection. It is one of the alternative materials of meltblown cloth. The characteristics of PTFE nano mask filter material are as follows 1. With the unique paste extrusion and biaxial stretching technology, the diameter of the fiber can reach below 100nm, and the cross-sectional area of the fiber is only 1% of that of PP melt blown fiber. The network structure formed by the staggered arrangement of these nanofibers has very good filtration efficiency, which can effectively protect bacteria and viruses, and has the characteristics of high efficiency and low resistance. 2. The filtration mechanism of PTFE nanofiltration material is pure physical filtration, long-term storage efficiency will not be reduced, safe and reliable; boiling water cooking or alcohol disinfection and sterilization efficiency will not decline, so it can be reused. 3. Compared with the common two-layer structure, PTFE nanoporous membrane and two layers of non-woven fabric have lower resistance, higher efficiency, and less damage risk in post-processing and use, which has obvious advantages.

Introduction to PTFE nanoporous films:

In order to avoid the risk of decreasing the efficiency of respirators in storage and use, electrostatic adsorption can not be used to supplement particles, but pure physical interception can be used to intercept particles. If we want to rely on pure physical interception to achieve efficient filtration, the size of the fiber must reach the level of nanometer number. The polytetrafluoroethylene (PTFE) dispersion resin can obtain fine fibers less than 100nm by biaxial stretching technology. The network structure formed by staggered arrangement of these nanofibers has very good filtration efficiency, which is enough to effectively protect bacteria and viruses. PTFE film has very excellent tensile properties. It can still be formed and rolled under hundreds of times of longitudinal and transverse stretching. The minimum thickness of PTFE nano film can be less than 1 μ m, and high efficiency can be obtained under very low resistance.

Now it's summer, the weather is getting hotter and the humidity in the air is getting higher and higher. The traditional raw material of mask meltblown cloth is particularly prone to electrostatic decay in wet environment, which will lead to non-compliance with the standard of filtration, while nanofiber membrane will not have this situation, so the nanofiber membrane stands out and becomes the best substitute for meltblown cloth.